STIHL battery production

How is a professional STIHL battery created? Read our article to find out more about battery production at the STIHL headquarters in Waiblingen in Germany. Take a look at our video to hear more about the process.

21.11.2024

Overview: Battery production

- We have been producing cordless products at STIHL since 2009

- We produce batteries in-house in Waiblingen, Germany, including the professional backpack batteries AR 2000 L and AR 3000 L from the AP System

- Production has many steps, from cell holder preparation to end-of-line test

- Maximum precision and various quality assurance measures are required to produce premium batteries

Battery expertise at STIHL

STIHL already has many years of battery expertise, as we have been manufacturing cordless products since 2009.

In 2016, the STIHL competence centre for battery and electric technology was established to combine the development of powerful battery and electric technology and to meet STIHL’s demand for performance and durability in modern cordless power tools.

Since 2018, STIHL has also been operating its own battery production facility in the same location as our development and competence centres.

How are STIHL batteries made?

What production steps are necessary and how does STIHL ensure that all of our batteries meet the high quality requirements during production? Take a look at our guide to battery production below.

In the first step, the cell holder, into which the battery cells are later inserted, is automatically fitted with special deflector plates. These contacts between the cells are laser welded to ensure they withstand high loads and give them a long service life.

STIHL uses Poka Yoke, a simple fault prevention technique, in this production step. The deflector plates can only be installed in the correct position. The cell holder is then transported to the next production line.

Once there, the prepared cell holder is equipped with battery cells by a pick-and-place robot. Two placement wheels present the battery cells in the correct orientation, which the robot extracts according to the respective placement pattern. In this battery production step, 60 battery cells are used for a STIHL AR 2000 L and a total of 90 battery cells for a STIHL AR 3000 L.

STIHL plastic production: STIHL’s own plastic production facility manufactures numerous plastic parts for the batteries, such as the holder for individual battery cells and the battery cover.

After the bottom cell holder has been equipped with battery cells, the top cell holder, which is also fitted with cell connector plates, is placed in the joining station and the battery cells are joined together. During this production step, the joining station automatically measures the force and distance to only send optimally joined battery packs for further production.

In the next step of battery production, the main electronics and sensors are inserted. First, the deflector plates are welded with high precision to the crimps of the electronic power line cables in a fully automated process. Then, among other things, temperature sensors are installed. These regulate the heat in the battery in order to prevent damage from overheating during use. After that, the medium-voltage taps are mounted using a patented design and also welded fully automatically.

Now the battery pack is fitted with a control unit. This is plugged in and wired first before the pretest is performed. This test verifies the proper functioning of the electronics with a beep.

This ensures that each manufactured battery pack functions correctly. This procedure reduces waste and contributes to sustainable production, as the controls can be replaced before casting and the battery pack can continue to be used if the pretest does not confirm proper functioning.

The battery pack and control electronics serial numbers are then married together. In this way, it is possible to see which specimens are installed in the finished professional battery. After passing the pretest, each specimen is prepared for casting.

The polyurethane encapsulation insulates the electronic components and protects them from moisture and mechanical influences. In the casting machine, the compound is applied under the PCB first to remove air. The polyurethane then rises until all components are covered. After the casting compound has hardened, the battery is ready for final assembly.

The first part of the final assembly is visually inspecting the casting and validating it with a white pen. The ergonomically shaped back plate is then mounted and equipped with fasteners and the handle. The operating unit is then plugged in and the front hood is attached. Before it is fed into the screwing station, the contacts are oiled as a preventive measure to ensure that they remain easy to connect for a long time.

The end-of-line test checks the functionality of the entire battery. For this purpose, the display LED is checked, the latest software is flashed, and all technical functions are tested to ensure safety during use in the field. After the inspection, all component labels are scanned and thus uniquely assigned to the specimen. The battery is only released for use once it has passed the test and the components have been assigned.

Finally, the professional battery is packed along with the accompanying documentation.

Important considerations in battery manufacturing

Electrostatic discharges pose a significant risk throughout battery production. Employees therefore wear special dissipative work clothing to effectively protect the still unprotected electronic components during production.

From cell assembly to end-of-line testing, STIHL has installed various quality assurance processes to provide the best quality for charging and use.

The sensitive components do not allow any error tolerances in the production processes. That is why every step of battery production requires maximum precision so that the finished battery meets the high quality standards we and our customers expect.

What is the future of battery production at STIHL?

STIHL is continuing to expand battery production at its headquarters in Waiblingen and will also produce the AP 500 S professional battery on site in Germany. At the same time, a new production facility for professional cordless products is being built in Waiblingen, which starts production from 2024.

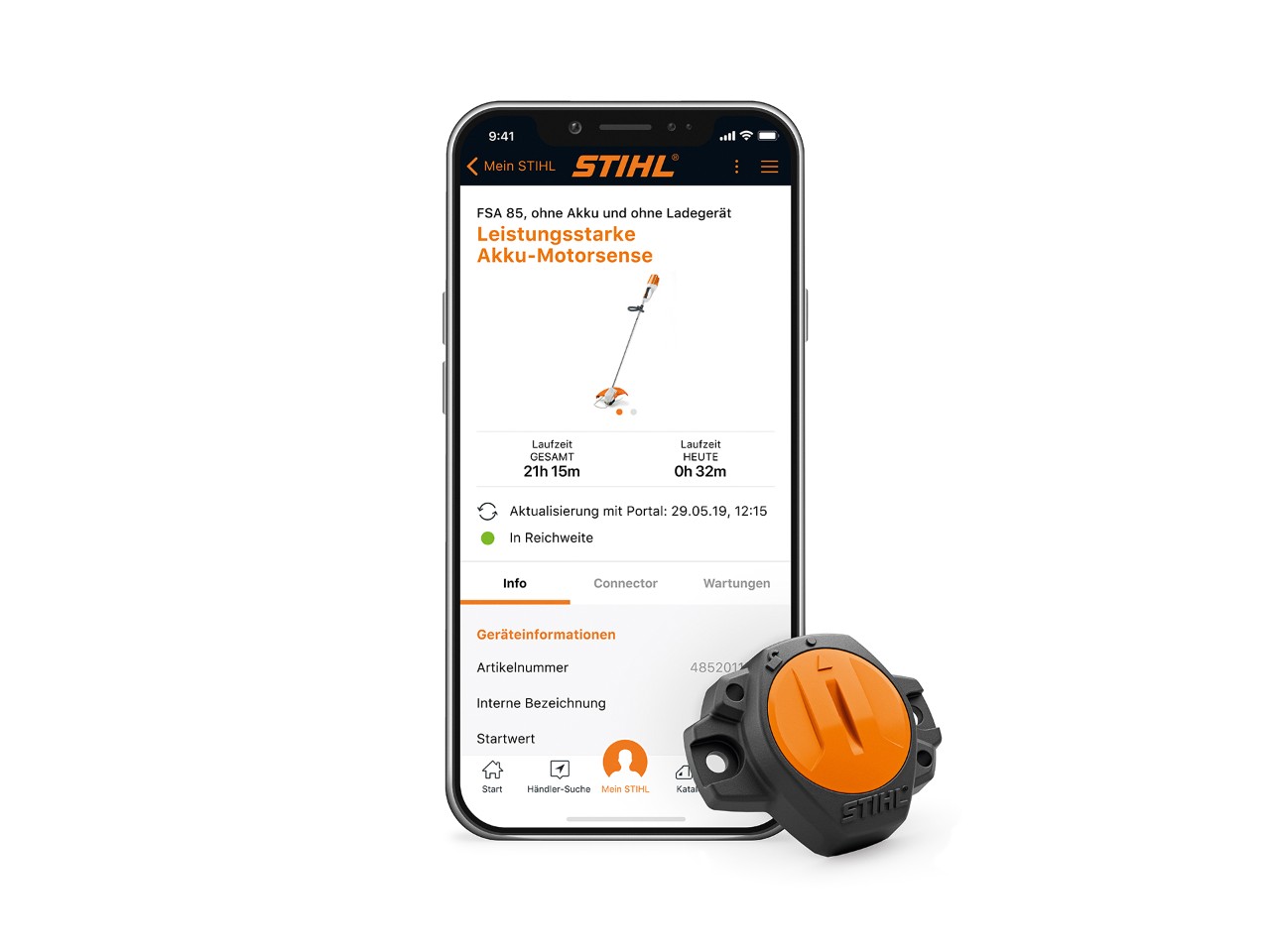

We are further developing smart batteries so that you can tailor the battery even more precisely to the application. This is achieved, for example, through smart charging technology that automatically adapts to the task in hand. This will mean that full power is available on time with maximum battery life in the future.